Safety & Health

We believe that every crane rental operation should be conducted with the utmost regard for safety. That’s why at STLPL safety isn’t just a priority—it’s a core value. We continuously invest in safety training, equipment maintenance, and hazard identification to mitigate risks and protect our employees, customers, and the public.

STLPL conducts Regular Site safety induction which provides essential information to ensure all personnel understand and adhere to safety protocols on-site.

We conduct regular audits to ensure safety standards are being adhered to and staff understand the standards to be followed to avoid incidents

Daily Toolbox Talk to discuss the Lifting Plans being conducted on the day and discuss any safety incident related matters.

There is a rigorous Pre-inspection of all equipment conducted before mobilization of equipment to site to ensure that the machine meets all the regulatory safety standards and requirements.

Rewards & Recognitions to award people following the best safety practices and thus encouraging people to elevate their standards and implement best practices across the industry.

Road Safety Day, Environment Day & other Fire Safety Mock Drills to create more awareness.

We believe in the welfare of our staff and provide the resources – ensuring that our staff are well hydrated during the intense summer heat by providing electrolyte and energy drinks.

“We believe that operation of heavy machinery And lifting should follow the highest safety standard. It is a non-negotiable”

Mass Meeting

A mass meeting focused on safety for heavy lifting involves organizing a gathering with an emphasis on proper techniques and precautions to prevent injuries and accidents related to heavy lifting. Also discussed during the meeting is planning and organization for critical lifts and checklist for equipment (belts, harnesses) inspection along with proper lifting techniques and creating awareness of the importance of use of personal protective equipment (PPE).

Crane Inspection

Conducting Inspection before commissioning to ensure no physical damage and functioning of control systems. Examining the cranes structural components such as boom, jib to ensure that no wear and tear or corrosion that could compromise integrity of the machine. Inspection of mechanical and electrical parts to ensure no parts are damaged or at risk. Ensuring that all the safety devices on the crane are functional.

Toolbox Talk Daily

Daily TBT Meeting to discuss the plan for the day and ensure that all safety requirements have been checked and whether there is a lift, assembly/dismantling of machine on that specific day and ensuring that the safety standards have been met. Discussion on inspection of equipment for the lift such as Sling, Dshackle, Belts and harnesses. Also ensuring that the operational area is clear of obstruction and there is no safety concerns.

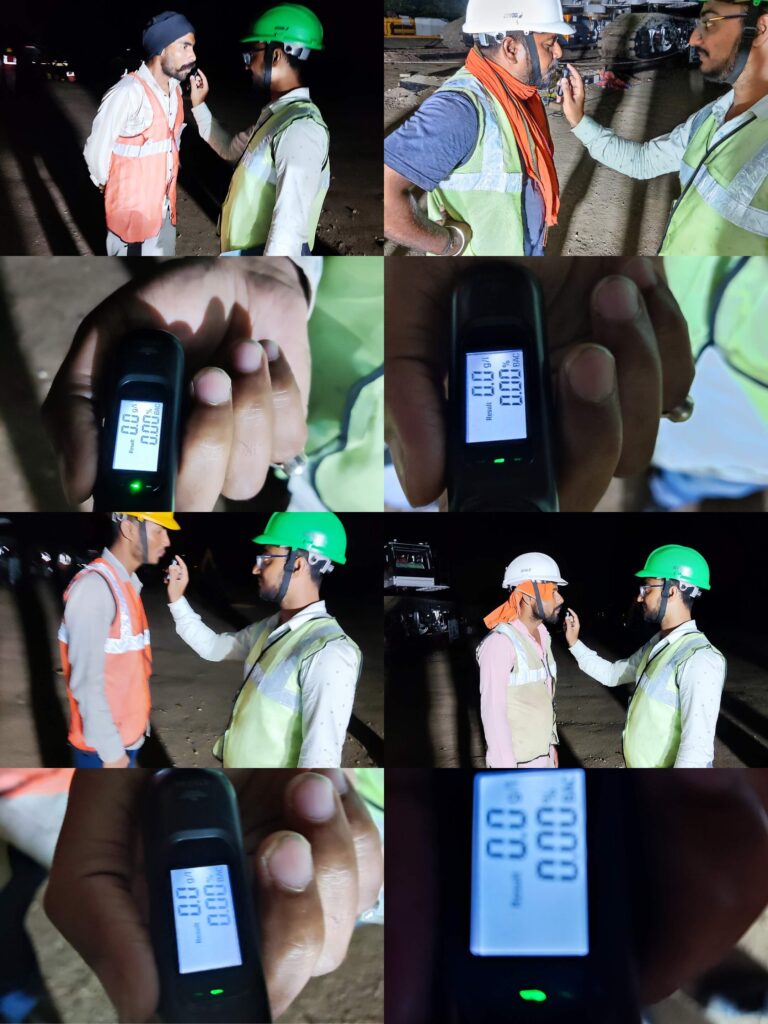

Alcohol Testing

A comprehensive policy that strictly prohibits the use Drug and Alcohol. The same is communicated to the employees to ensure that they understand the consequences of non-compliance and educating them on the hazards of being under the influence of these substances. Conducting of random tests without prior notice to ensure compliance.

Fire Safety Training

Fire Safety Training in Office Premises

Fire Safety Training at Job Site